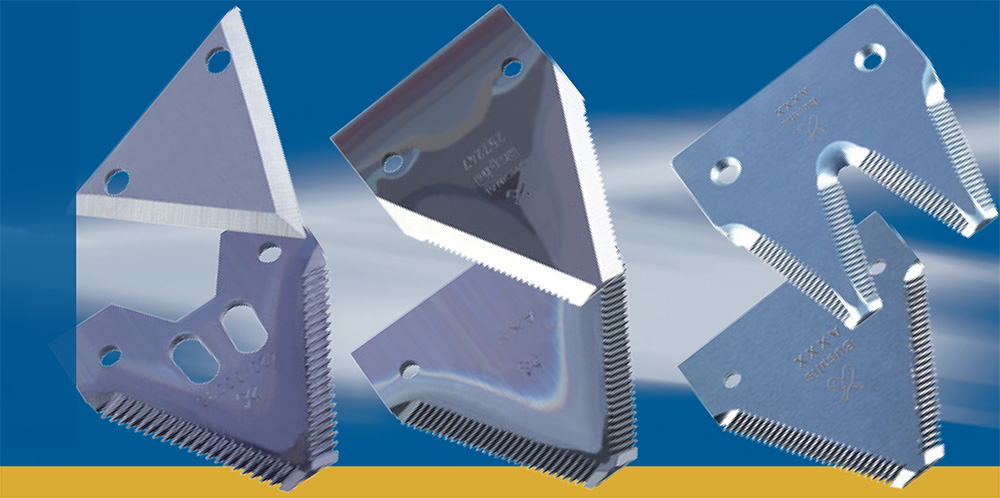

Sickle sections

Busatis develops and manufactures quality sickle sections according to the specifications of our customers. The products are made of special alloy tool steel. Busatis delivers quality sickle sections to leading manufacturers of agricultural machinery.

Advantages of the Busatis quality sickle sections:

-

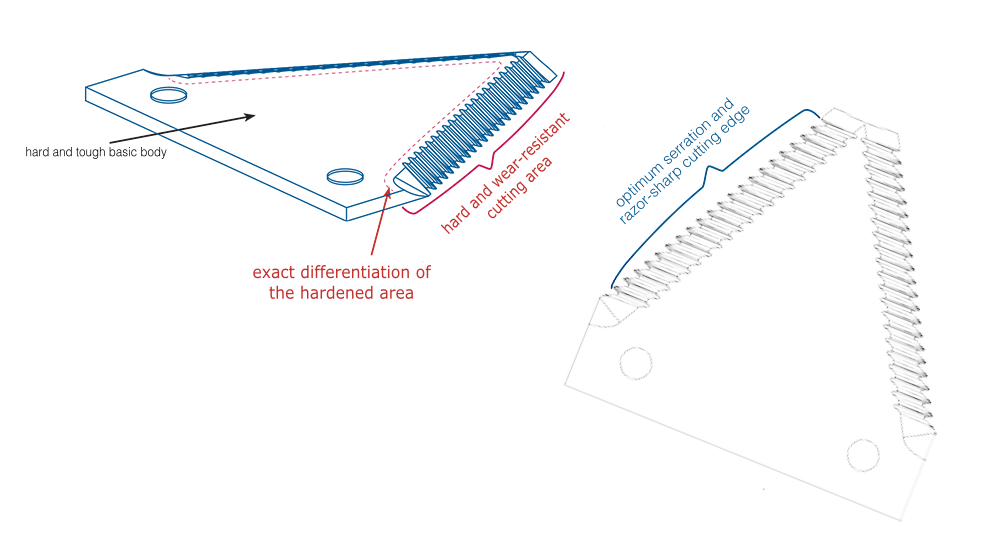

high cutting performance due to chrome alloy and high hardness in the cutting area

-

little risk of breaking due to special alloy tool steel and exactly defined hardness area in the cutting area

-

high bending strength due to cold rolled steel strip and specific heat treatment techniques

-

easy assembly due to dimensional accuracy and smooth surfaces

technical features of Busatis quality sickle sections

It is important to cut the stalks as efficient as possible using a razor-sharp cutting edge in order to reduce the risk of losing grain especially when it is overripe. Additionally, a reduction of the knife’s cutting force as well as the machine power needed can be obtained. Ensuring the high cutting performance of the sickle section, its cutting area must be hard and wear-resistant. The sickle section should not bend or break when being blocked.

Areas of use | Type of sickle section | Advantages |

|---|---|---|

Fine grass | Smooth sickle section | Low risk of blockage |

Ordinary grass | Sickle section with serration at the bottom | Regrinding is possible |

Grain | Sickle section with serration at the top (“fine”) | Self-sharpening |

Grain and grass with stalk | Sickle section with serration at the top ("regular", "medium") | Self-sharpening |

Coarse, dry grass, rocky conditions | Sickle section with serration at the top “coarse”, “xcoarse” | Aggressive serration |